To get the best out of your Winton Finishing Mower, it is important to keep your machine well maintained and regularly serviced. This is a brief guide to the maintenance routines which will allow you to continue to have the optimum results from your mower, and prevent a breakdown.

Blades

If blades are dented or wonky on the blade shaft, they will not leave an even finish when cutting the grass. A finishing mower’s selling point is its fine finish on the grass, so this is best avoided. Regularly check the condition of the blades and replace them if they are work or broken. WFM blades are available from Farm Tech Supplies.

To replace the blades, raise the mower off the ground so the undercarriage can be reached, ensuring the mower and tractor are stationary and the key is out of the ignition. Use a size 30 spanner to hold the blade shaft and a size 27 to twist off the nuts (circled). Then remove the old blade and replace it with the new one, taking care to make the blade as secure as possible when retightening the bolts to avoid excessive vibration when the machine is in use. It is advisable to wear gloves when handling the blades.

Oil and Grease

Keeping your machine well-oiled and greased is vital to its continued smooth running. The WFM gearbox requires an oil change after 50 hours of work when you first buy it, and after that every 250 hours of work, or yearly, depending which comes first. The manual included with your machine contains a handy log to keep track of your oil changes.

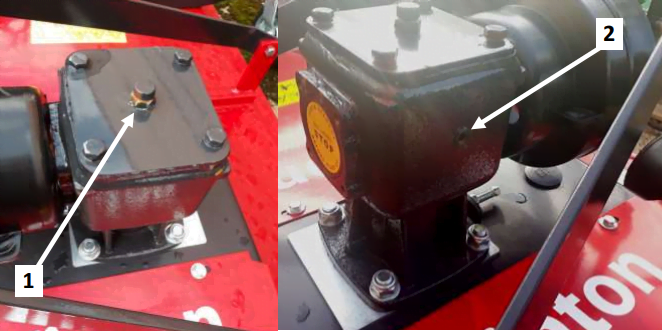

Always make sure the machine is on a flat and level surface when checking oil levels. The machine should be left stationary, detached from the tractor, to cool down for at least 10 minutes. Use an oil pump to remove old oil and any debris. Always dispose of old oils in a suitable place, such as your local waste disposal centre, in a sealed plastic or metal container. Remove the breather plug (1) on top of the gearbox unit, and remove the level plug (2) on the side of the gearbox, with an 8mm Allen key. Add oil through the breather hole (1) (if required), until the oil reaches the bottom of the level plug (2). You will need 80w90 API GL5 grade oil, available from our spares department. Finally, replace breather plug (1) and level plug (2).

There are also multiple points that need regular greasing on the WFM, namely on the blade hubs (underneath the bungs on the top of the mower), wheel fork tubes, wheels, and the PTO shaft. Wipe the grease nipples with a clean cloth before greasing to avoid injecting any dirt or grit. Then press grease into each grease nipple until no more grease will go in. We recommend using a hand-held grease gun for best results.

Belts

Belts can loosen and fray over time so it is important to check them before each use. The correct belt tension is achieved when the belt can be pushed in by 10mm at the centre point between the pulleys. A generic measure is that the belt should be able to twist a quarter turn by hand. Any more and they are too loose and any less, they are too tight, so you may run the risk of losing drive to the mower or burning the belts out prematurely.

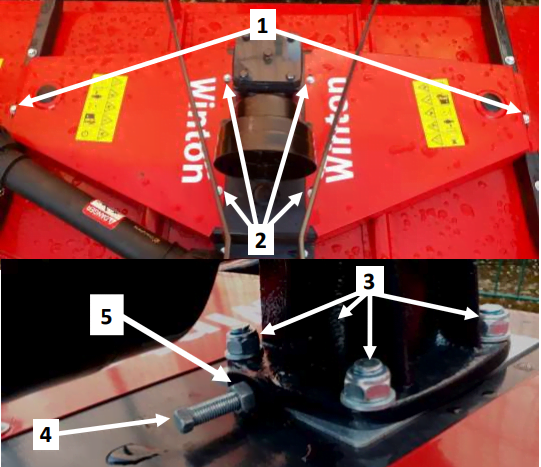

To change or tension the belts, remove bolts (1) on the wheel brackets then bolts (2) on the guard by the gearbox. Remove both belt guard panels to gain access to the belts, then loosen off bolt and nuts (3). Wind in/out bolt (4) and nut (5) to tension the belts as required, or loosen it to take the belts off and replace them. Finally, replace and tighten bolt & nuts (3), replace belt guards, then re-tighten the bolts (1 & 2).

General

Without the PTO shaft, the Winton Finishing Mower will not run so it is essential that you check on the condition of your PTO frequently. If it becomes worn or damaged, it should be replaced immediately. An in depth look at PTO maintenance and safety can be found in our previous blog, Safety 101 – PTO Shafts.

Likewise, the wheels need to be checked regularly and replaced if there is any damage or excessive wear. The full wheel assembly, as well as all the separate components are available from Farm Tech Supplies.

The bearings on the three blade hubs should be checked often for best results from your mower. If the oil seals are damaged, debris may enter the bearings, so keep them clean and replace with new bearings if necessary. Run the mower without a load for approx. 3-5 minutes to check whether the bearings are operating smoothly.

Keeping the machine clean and sensibly stored is also important. Ensure the mower deck is clean of mud and grass, and remove debris from all the moving parts to prevent entanglement. Do not spray water on bearings when cleaning with a high-pressure washer. Any chipped painted should be re-coated to prevent corrosion. We advise you store the machine in a dry, level area so it may be necessary to chock the wheels.