Getting the cutting height right is the key to creating the best cut and finish when mowing with a compact tractor flail mower. One of the benefits of a flail mower is that on its lowest setting, the blades can achieve a finish similar to that of a finishing mower, but also on the highest cutting settings clear brambles and weeds like a topper mower. The cutting height needs to be adjusted depending on the evenness of the terrain and also the length of grass and density of weeds. It is also best for the health of the grass to raise the cutting height in dry weather.

The general rule of thumb is to avoid chopping off more than a third of the grass length on regularly maintained areas such as lawns. Although, no need to apply the same rule to those pesky overgrown areas and weeds, the flail can slice through those often in a single pass.

The cutting height can be set for longer grass by simply raising the hydraulic lift arms on your tractor to take a higher pass for very overgrown areas so the mower is floating on the linkage. But usually, this is altered by adjusting the rear roller and skids on the flail mower, adjusting both correctly with the length of your top link arm can also optimise the efficiency of the mower. All the Winton flail mowers have a minimum clearance of the blades to the ground of at least 30mm, only 10mm more than a finishing mower. The roller and skid adjustment process are essentially the same across all Winton flail mowers.

Roller Adjustment

The roller not only evens out the grass after clipping, but the position of it can also change the angle of the main body of the mower. This can either raise or lower the height of the blade rotor in the middle of the machine.

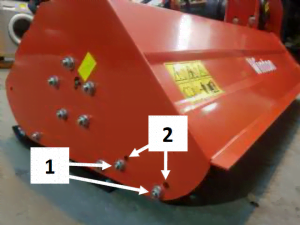

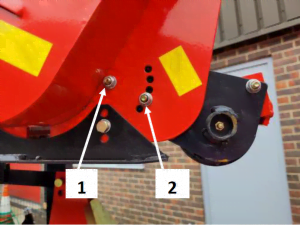

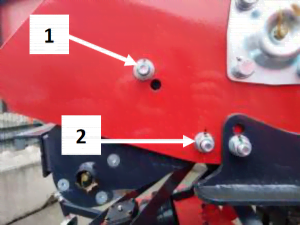

In order to change the position of the roller, remove the bolt (1) on both sides of the machine. Then adjust the roller by aligning the selected hole in the roller support bracket at the correct position (1), pivoting around the second bolt (2) (using the hole closest to the ground gives the highest working height). This is where the Winton flail mowers do differ slightly. The adjustment holes are located on the roller bracket on the WFL and WHF types, whereas they are on the main body of the machine on the WVF and WCF. Finally, replace the bolt (1) into the selected hole and re-tighten it.

Skid Adjustment

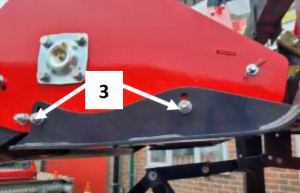

The skids support the main body of the machine as it passes over the grass and prevents the blades scalping the ground on uneven areas, so adjusting the height of the skids is one of the main ways of adjusting the cutting height. They can be bolted to the inside or outside of the main body, but must not touch the belt guard or the rotor bearing.

When adjusting the skids, remove the nuts and bolts (3) on the front and back of both sides of the machine. Then move the skids up or down to the desired bolt hole height and re-insert bolts and nuts (3) and re-tighten them.

The ideal set up should have the flail mower skids parallel to the ground and the rear roller just touching the ground. The adjustable top link arm on the tractor can be twisted in or out to angle the mower to get this desired position. Remember the flail should not rely solely on the skids or roller to run along the ground when mowing, this will call excessive strain on the roller bearings and wear down the skids especially on uneven terrain. Having the mower relying on the tractor’s linkage vs. the roller/skids is a much better set up for long term performance.

Although setting the correct cutting height on your Winton flail mower is a relatively simple process, it will help you get the best out of your machine. Not only will it help you achieve the desired finish on your grass, but also help to maintain your mower and prevent unnecessary damage.