The Winton Verge Flail Mower is incredibly versatile, with the capability to mow not only lawns, but also verges, ditches and even small hedges. To keep its full range of use, it is important to keep this machine properly maintained. Please make sure the tractor and mower are stationary and the keys are out of the ignition before attempting any works.

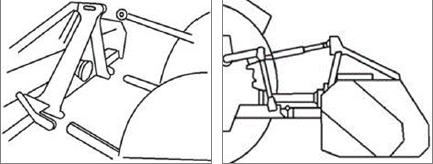

Attaching the Mower

- Start by finding a flat piece of ground. Lower the 3-point linkage on your tractor to its lowest position and attach the mower to the tractor using the three point linkage pins and linch pins.

- Attach the hydraulic connections.

- With the rear roller of the mower on the ground, adjust the length of the top link arm and use the tractor hydraulics to ensure that the skids at the side of the flail mower are parallel with the ground when horizontal.

- Rotate the blade rotor by hand so that a row of blades hang vertically towards the ground to give an idea of the cutting height. Check the clearance between the bottom of the blades and the ground, this should be at least 30mm. The cutting height can be set for longer grass by simply raising the hydraulic lift arms on your tractor or/and by adjusting the rear roller and skids on the machine to increase or decrease the blade clearance as required.

- Check your PTO shaft’s grease points and apply grease if needed. Then attach the PTO drive shaft and ensure the locking pin is secure on both the tractor and mower sides.

- Attach the chain to a secure point on the tractor/implement. Operate the flail mower with the tractor in low range gear and the PTO delivering 540 RPM.

Adjusting Cutting Height

Getting the cutting height right is the key to creating the best cut and finish when mowing. This needs to be adjusted depending on the lay of the land as well as the length of grass and density of weeds. The cutting height can be set for longer grass by simply raising the hydraulic lift arms on your tractor or/and by adjusting the rear roller and skids on the machine.

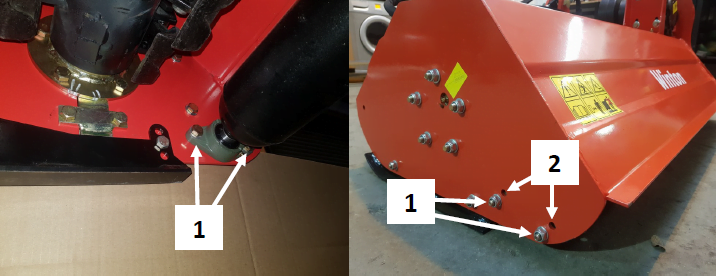

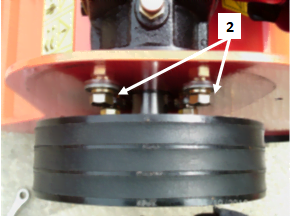

Roller Adjustment

- Remove bolts (1) on both sides of the machine to adjust to desired height.

- Adjust roller by aligning the selected holes in the roller support holes at position (2) (using the hole closest to the ground gives the highest working height).

- Put bolts (1) into the selected holes (2) and re-tighten bolts (1).

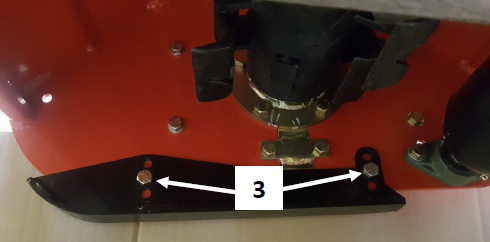

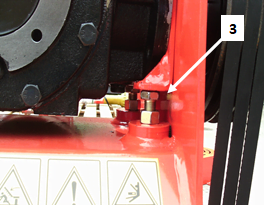

Skid Adjustment

- Remove the nuts and bolts (3) on the skids on the front and back of both sides of the machine.

- Move the skids up or down to the desired height with the set holes on the skids.

- Re-fit nuts and bolts (3)

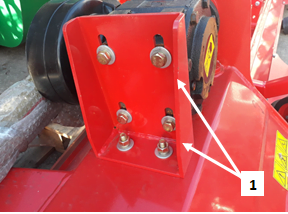

Adjusting Belt Tension

The correct belt tension is achieved when the belt can be deflected by the belt thickness about 10mm at the centre point between the pulleys. Tension should be checked regularly. A generic measure across machines is the belt should be able to twist a quarter turn by hand. Any more and they are too loose and any less and too tight, you may run the risk of losing drive to the mower or burning the belts out prematurely.

- Remove the belt cover.

- Loosen the four bolts (1) securing the gear box to the mounting plate.

- Loosen bolts (2) behind the belt cover holding the support shaft.

- Loosen off the counter locking nuts (3).

- Adjust belt tension by adjusting the height of counter nuts (3).

- Align the gearbox ensuring the drive shaft is parallel with the body and re-tighten nuts.

- Re-tighten all bolts.

- Replace the belt cover.

Always use a straight edge to make sure the belt pulleys are in line and running true. If misaligned, call your dealer or service engineer for technical support.

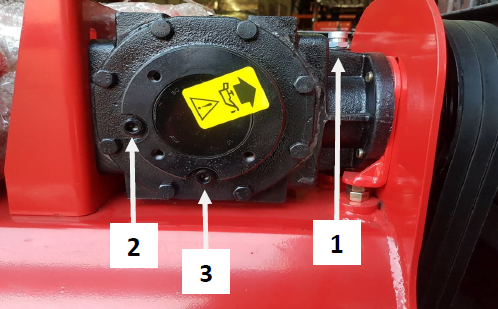

Gearbox Oil Check/Change

Always check oil when the machine has cooled down and on a level surface. Make sure bolts are tightened correctly. The filler/level plug should be secure but not over tightened.

- Remove the filler/breather plug (1) ready to add oil if needed.

- Remove level plug (2) to check oil level.

- Remove drain plug (3) if oil is overfilled or ready to be drained, replace once oil is drained.

- Add oil (80w90 gear oil) through the filler/breather plug hole (1) until it begins to seep out from the level plug hole (2).

- Re-install both the plugs (1 & 2) once filled.