The Winton Finishing Mower gives a precision cut perfect for lawns and sports pitches. A precision machine needs to be kept in tip-top condition for the best results, so here are the basics. Always ensure that the tractor and machine are stationary, and the keys out of the ignition before attempting any work.

Cutting Height Adjustment

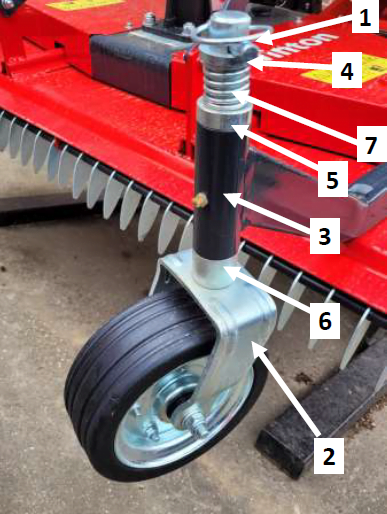

Getting the cutting height right is the key to creating the best cut and finish when mowing. The cut height can be set by simply adjusting the mower deck height with the wheel spacers. There are different sizes of adjusting spacers on the wheel forks which can be used to achieve a range of cutting heights. The spacers are moved from under and above the wheel bracket to achieve the desired height. Always make sure all spacers are in the same position on all wheels to ensure an even and level cut.

- Use the tractor linkage and secure stands to raise the mower off the wheels.

- Remove linch pin (1) and slide wheel fork (2) out of bracket (3).

- Position spacers (4, 5 & 6) above or below the wheel bracket as required.

- Position the spring (7) on the bracket.

- Replace wheel fork (2) and linch pin (1).

- Repeat above on the remaining three wheels.

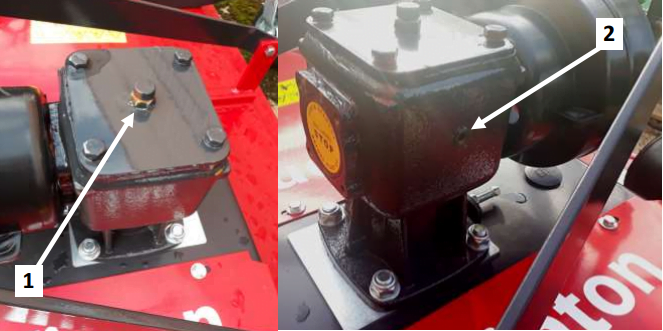

Gear Oil Check and Change

Do not mix old and new oils together or mix different types of oil. Always dispose of old oils in the safely and in the correct manner. Always make sure the machine is on a flat and level surface when checking oil levels. The machine should be left at a standstill to cool down for at least 10 minutes. Ensure the machine is stable before carrying out work and will not upturn then:

- Remove filler/breather plug (1) on top of the gearbox unit.

- Remove level plug (2) on the side of the gearbox.

- Add oil (80w90 gear oil API GL5 grade) through the filler/breather (1) (if required). The oil should reach the bottom of the level plug (2).

- Replace filler/breather plug (1) and level plug (2).

Use an oil pump to remove old oil and any debris when changing oil. Always make sure bolts are tightened correctly. The filler/level plug should be secure but not over tightened.

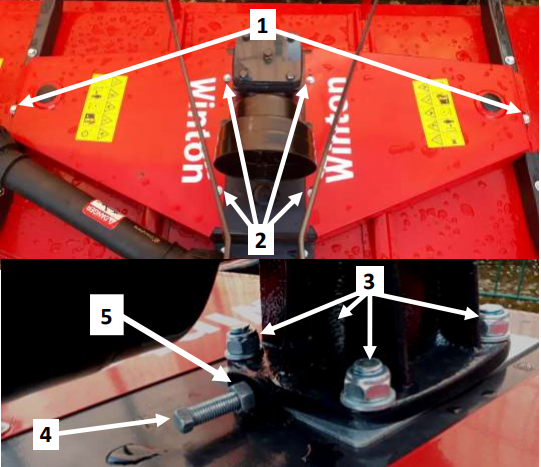

Adjusting Belt Tension

The correct belt tension is achieved when the belt can be deflected by the belt thickness about 10mm at the centre point between the pulleys. A generic measure across machines is the belt should be able to twist a quarter turn by hand. Any more and they are too loose and any less and too tight, you may run the risk of losing drive to the mower or burning the belts out prematurely. Always use a straight edge to make sure the belt pulleys are in line and running true. If misaligned, contact your dealer or service engineer for technical support.

- Remove bolts (1) on the wheel brackets then bolts (2) on the guard by the gearbox.

- Remove both belt guard panels to gain access to the belts.

- Loosen off bolt & nuts (3).

- Wind in/out bolt (4) and nut (5) to tension the belts as required. To change belts, loosen off the belt tension. They are a tight fit and will need some elbow grease.

- Replace and tighten bolt & nuts (3) and replace belt guards.

- Replace and tighten bolts (1 & 2).

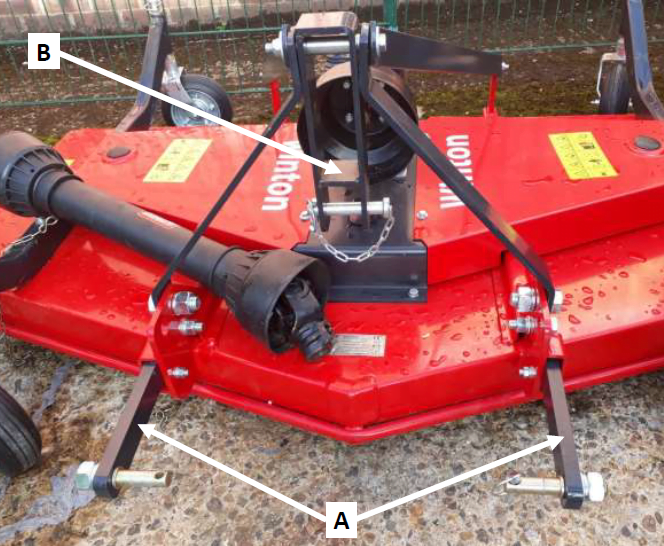

Linkage Extension

Some tractors with shorter lower linkage arms or larger rear tyres may find that attaching the finishing mower causes the tractor wheels to touch the mower wheels. In these cases, linkage extensions can be supplied to prevent this problem.

The lower linkage extenders (A) can be attached or detached as required. These are simply bolted to the A frame bracket on the mower. The lower linkage pins can be moved between the extension brackets and mower as needed. The mower also has a floating top linkage (B). This is not fixed into place which allows the mower to remain on all wheels over any bumps or contours in the ground. Lift the floating linkage (B) by hand and attach to the tractor as you would with a fixed top linkage point. Adjust the tractor’s top linkage arm so the linkage is secure.

Always take extra care if lifting the tractor’s 3-point linkage when the mower is attached. As the floating top linkage is not rigid the mower is likely to be unstable. Use a fixed point for any lifting.